General News » News

Local school e-nables helping hands around the world

February 10, 2016 · 0 Comments

By Brock Weir

As a teacher and parent, Terry Prezens knows “kids have great hearts.”

A computer sciences teacher at St. Andrew’s College, he has guided his students in using technology and resources at their disposal to devise ways to better the world around them.

“They do stuff because they are not afraid of failure or what the world is going to think of them so much,” says Mr. Prezens. “If you tell them what they can do, and you explain to them how the world will benefit from it, it is a no brainer.”

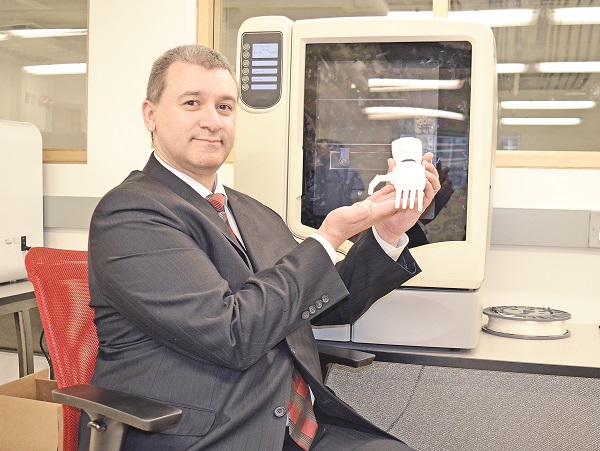

But Mr. Prezens recently played the waiting game – not afraid of failure necessarily, but certainly curious as to what a few people around the world thought of something he made: a prototype hand produced by the school’s 3D printers.

Working on models created by e-Nabling the Future, Mr. Prezens stumbled into the initiative which connects 3D printer-equipped individuals, organizations and schools around the world with those in need of cost-effective artificial limbs.

Reading more about their efforts, becoming involved also seemed a no-brainer to Mr. Prezens and he set about downloading their plans and working out the kinks on their in-house machines.

“The first one that came out was terrible,” he says with a laugh, “but when it finally came out, it was pretty good. I printed off the hand and sent it to them in early October. It took them more than two months to get back to me because they want to see the quality of your hand. You don’t want them to partner with a child and then have a product the child is not happy with or [promise] something you can’t deliver.”

Just a few short weeks ago, however, they reached their verdict.

Testing it for strength, quality and durability, they gave SAC the green light begin printing out more hands for the group effort.

Printed out in white plastic, which has been donated to the school by parents, the artificial hand is flexible with articulated joints at the fingers.

As long as the wearer has a wrist, a simple flex can open and close the fingers. If the wearer does not have a wrist, stationary hands are also possible.

The end result, cautions Mr. Prezens, is not a true prosthetic but an aid to add more “functionality” in the everyday life of the wearer, even if it is something as simple as allowing someone to hold onto both handles of a bicycle for the first time.

In Mr. Prezens’ classroom, students are taught to build things with a purpose.

If you can give a kid a real-world problem, the learning is “way better,” he says.

Some of the real-world issues they have addressed includes a GPS wristband system where kids on the autism spectrum can check in with their parents (and vice versa) and t-shirts with sensors to help guide the visually impaired.

In this case, the blueprint for the hand was already at the ready.

They estimate a similar product done by a professional could cost up to $8,000 per limb. For SAC, whose printers have been donated by parents, their cost to produce each hand might run up to $60.

While the teacher happy their finished product has been accepted by e-Nabling the Future, there is still a sense of unfinished business.

He has not yet received word if this first hand has found a lucky recipient locally or internationally.

“It would be nice to make one for somebody, to have some child actually benefit from having a hand they otherwise couldn’t get because they just couldn’t afford it at $8,000,” he says. “If you are a parent, you want your child to have this prosthetic but the child is growing so fast; do you spend $8,000 and, in a year, they will outgrow it? $8,000 is a big chunk of change for most people.

“If we just help one person that will be amazing. That change of just helping one person is huge. There has already been success by the fact we brought [this issue to] the attention of students, faculty and staff and the possible solution we have. When I showed the kids the hand, they wanted to know what it was, but when you tell them how other people need it and how some people can’t afford it, many of them hadn’t even considered that as a possibility. Just bringing that up and making them think about it is a bit of a success.”

But, with the go-ahead from the designers, they are eager to turn this success into making an impact as soon as possible.

If someone locally or globally needs an artificial hand, SAC could theoretically do it themselves and print it as the program comes with instructions on how to make to measure, but are cautious they could be inundated with requests.

Mr. Prezens says it might be a better idea to connect with the initiative online at enablingthefuture.org.

Nevertheless, there is a sense that Mr. Prezens, a father of a daughter who faces her own challenges with Down Syndrome and living on the autism spectrum, is itching to simply get down to business.

“If someone needed one, we would be okay going for it,” he says. “I want to help some child and we have the ability to do it. If they need it and they can’t afford it, I say we go for it!”